After you are finished with the article, Click below to try it yourself with our

In this article we are going to go through the steps required to design the most efficient modular drawer storage cabinet for you application. By following these steps, you will maximize the storage capacity of your cabinet or drawers in shelving. Although we focus here on cabinets here, the same procedure would work for drawers installed in shelving units.

We work with Rousseau Metal products that are made in North America. All Rousseau Modular Drawer Cabinets and Drawers-in-Shelving use Standard North American Dimensions and are compatible with most standard shelving brands and sizes.

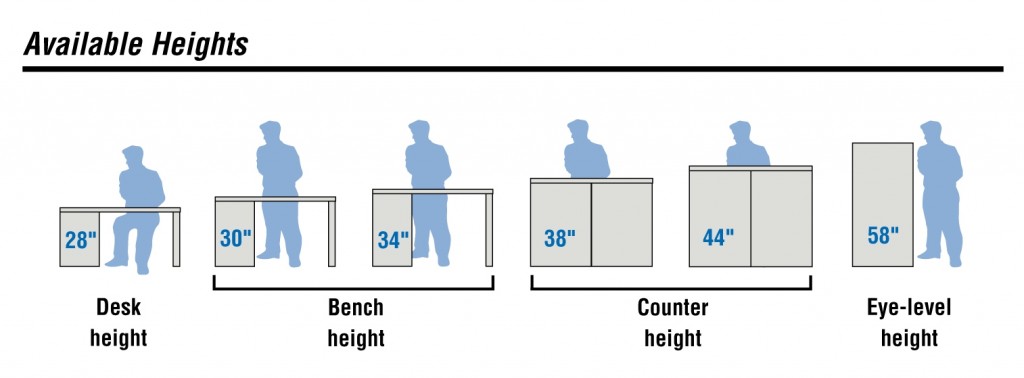

1. Determine the Cabinet Height & type of Base.

Common Height Options (other heights are available):

28”- Desk / 30” or 34”- Bench / 38” or 44”- Counter / 52″ or 58”- Eye Level

Common Base Options (add to the overall cabinet height):

The standard base is a 2” high forklift-able base; raises the overall cabinet height by 2”.

Optional 4” high base, accessible by pallet jack, raises the overall cabinet height by 4”.

The cabinet can also be ordered without a base if vertical clearance is limited.

2. Decide on the Width and Depth of the cabinet

Available Widths: 24”, 30”, 36”, 42”, 48”, 54″, 60”

Available Depths: 18”, 21”, 24”, 27”

The most common sizes are 36″ or 48” wide x 24″ deep, as these sizes will match standard North American shelving sizes.

Another common size is 30” wide x 27” deep; a close match to some metric measured cabinets.

3. Determine the best Drawer Heights for your products.

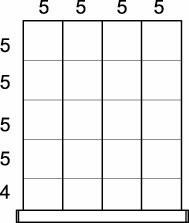

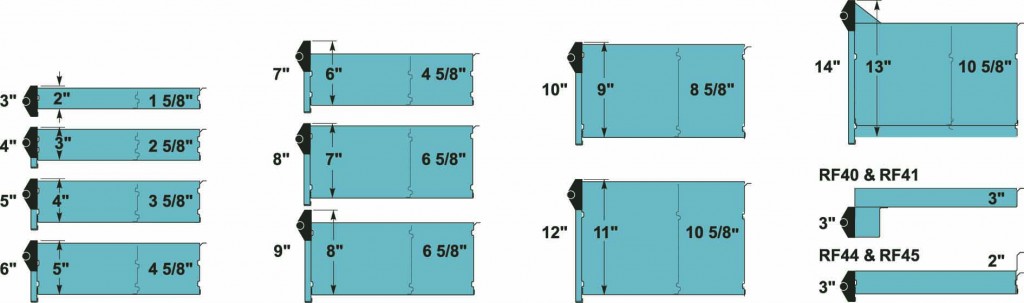

Available Drawer Face Heights: 3” to 10”, 12”, 14” and Pull-Out Flat Shelves (3” base height). All drawers have a 400# capacity with full extension, 100% of the drawer interior will be visible. The Usable Height inside each drawer is 1” LESS than the Face dimension of the drawer.

The space available for drawers in a cabinet is 4” LESS than the Cabinet Height you chose.

Therefore a 58” eye-level cabinet would have 54” of usable space for drawers, a 30” bench height cabinet will have 26” available. You can install any combination of drawer heights that makes up the available space, based on the face dimension of the drawers.

Try to match the Usable Drawer Height, as closely as possible, to the products being stored. Usually this involves a full review of your products, including sizes and quantities of the items to be stored in the drawers.

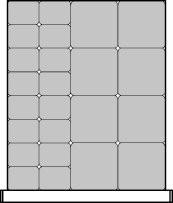

4. Decide which (if any) Insert Options you want in each drawer.

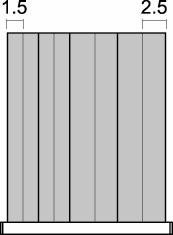

Internal Drawer Configurations can include Partitions (front to back, fixed) and Dividers (left to right, adjustable), removable Bin Cups designed to fit the drawer exactly, Groove Trays for long, thin items, PVC Drawer Liners, or Foam Inserts for protection or for tool cut-outs.

You can have different layouts in each drawer. Drawer compartment layouts are specific to each drawer size. You can request a drawer compartment layout option sheet for the cabinet size you have chosen.

For smaller fasteners and parts, we recommend bin cups in some of the 3” or 4” face drawers, rather than partitions and dividers, as they are easier to pick from and can be removed for use at a work station, or for ease in sorting or counting of parts.

5. You can call us, fax us, or email us with your specifications and we will provide free quotation within 24 hours.

6. OR, Try it Yourself with our Online Cabinet Design Tool

Phone: 401-383-0883 Fax: 401-354-6610

Email: support@innovostorage.com

Want this information on a one-page PDF file?

Click Here: Designing a Drawer Cabinet

Innovo Storage Systems, 1 Goldsmith Street, Johnston, RI 02919 (401) 383-0883