So, you have decided to opt for maximum space utilization by organizing and storing your parts or inventory items by size, rather than in numerical order. This will allow you to customize the shelf spacing and the modular drawer heights for each group of components. But now, you think it may be harder to find items than it was when they were in straight numerical order. Well, let me help with some ideas that may actually decrease the time it takes to find items.

First of all, we should all be using computers to help us track our inventory. There are many off the shelf inventory tracking programs that allow you to record item number, type, vendor, cost, stock levels and, most important for our purpose here, storage location. A simple data base can be created to serve the same purpose or even a spreadsheet with the key pieces of information. Once entered, the information in a spreadsheet can be sorted by part number, enabling you to look up the location of any part on screen or on a printout. Many software programs now allow you to print picking lists in location order, rather than by part number.

Beyond using the computer, there are other ways to organize your components to minimize search time in your stock area.

- If you can obtain an analysis of your fastest moving items (your Top 20%), those items can be moved to the most convenient location for picking. These typically make up 80% of the active picks and you can reduce search and retrieval time considerably.

- You can group items by type, making it easier for workers to find items that way. Shelving can be labeled or color coded to indicate the type of product. In modular drawer systems, each group of drawers, or even individual drawers, can be labeled or color coded by type for faster access to different product groups.

- Instead of organizing strictly by type, you can group by size and then type. For example, storing a group of bolts that can range from #6 (very tiny) to 1″ diameter (very big) in the same drawer or on the same shelf makes sense logically (keeping all the Bolts together), but not with respect to space efficiency. Storing all those tiny #6 bolts, along with their matching nuts, washers and lock washers together will be the most efficient use of space.

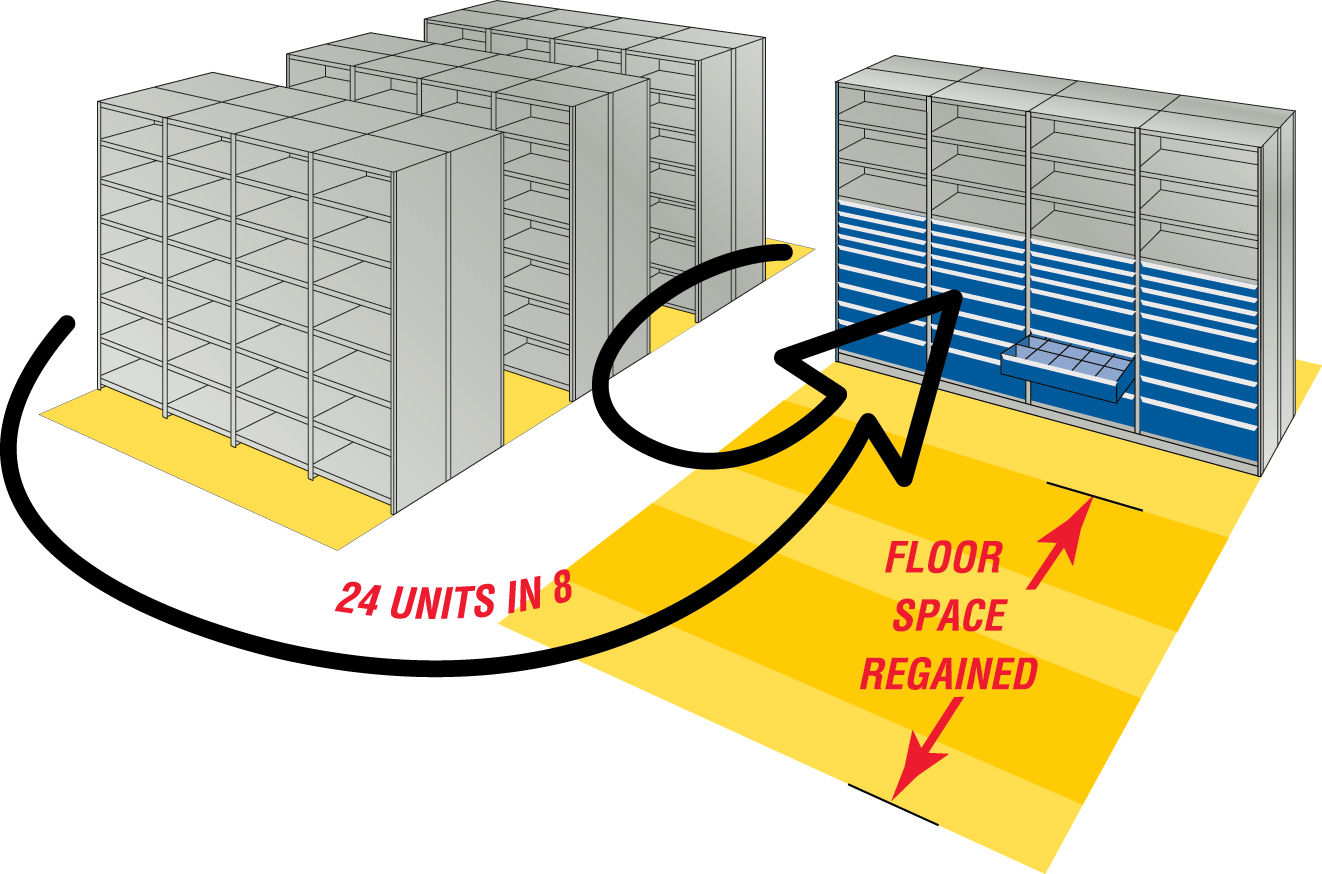

- The use of Drawers-in-Shelving can increase the number of items that can be stored in the same amount of space. Designing a drawer layout to match the size of the items you need to store will maximize the efficiency of your storage. More items in less space means less walking and less searching to find the right item.

Keep in mind that every business operation is unique. These general guidelines can help you get started, but we encourage you to engage the people who will actually be working in this area to provide new ideas and feedback with their suggestions. Having everyone fully involved in implementing a new system will ensure a smoother implementation.

Visit our website to learn more about 5s lean organization.

Innovo Storage Systems 1 Goldsmith Street Johnston, RI 02919 (401) 383-0883