DRAWERS IN SHELVING

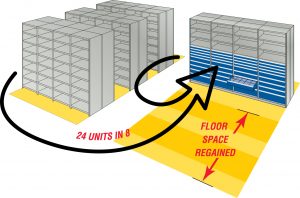

The drawers-in-shelving concept for saving space is based on the fact that drawers in shelving allow for denser storage while at the same time providing better visibility for all parts within each drawer due to the full extension capability of the the drawers. Typical applications can gain back from 25% to 50% of the space used compared to conventional bin type shelving.

Drawers in shelving is one of the most efficient options for increasing storage space. Drawers can be added in existing bin shelving or purchased as part of a new shelving system. Drawer insert sets for shelving can be of different heights that range from 12″ high to 48″ high within the shelving. The heights of the drawers in the set can be customized to suit your particular application. Drawer heights for drawers in shelving range from 3″ face to 14″ face, with the usable height inside the drawers at 1″ less than the face height. Drawers in shelving units can also be supplied with roll-out flat surface shelves for easier access of heavy cartons, jigs, or parts without having to lift the product out of an enclosed drawer.

Modular Drawer Cabinets

48″ Drawer Set 36″ Drawer Set 24″ Drawer Set 18″ Drawer Set

Drawers in shelving are used to maximize storage efficiency in many industries, such as: automotive parts storage, Industrial MRO maintenance and repair facilities, wholesale distribution of small parts for manufacturing, small engine repair, electronic parts, HVAC plumbing and heating suppliers and medical device storage. Drawers in shelving provide easier access and efficient storage for a wide range of part sizes.

Drawers in shelving are used to maximize storage efficiency in many industries, such as: automotive parts storage, Industrial MRO maintenance and repair facilities, wholesale distribution of small parts for manufacturing, small engine repair, electronic parts, HVAC plumbing and heating suppliers and medical device storage. Drawers in shelving provide easier access and efficient storage for a wide range of part sizes.

Drawers in shelving can be configured with many options to maximize storage efficiency.

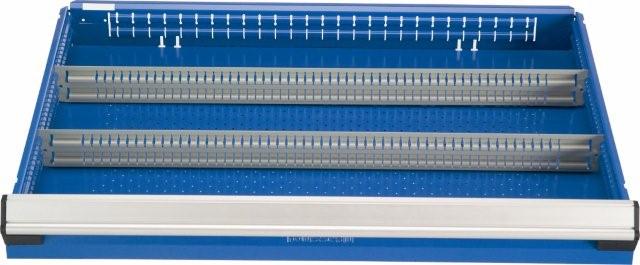

Partition & Divider System

Partitions are the separators that go from front to back in the drawers. They install in slots in the drawers and are held in place with 2 small screws that are easily removed to re-position the partitions.

Dividers go left to right, snap into place between the partitions, are adjustable on ½” centers, and can be installed anywhere in the ‘lanes’ created by the partitions.

Determine the best width between partitions for your products. Then choose how many dividers you will want in each lane created by the partitions. We have several standard layouts that are shown on a separate sheet, but we can customize any layout to suit your specific application. The usable space in any compartment is about ½” less than the nominal spacing of the partitions and dividers.

Although most Partitions are usually installed from front to back, we do offer partitions that go from left to right in the drawer. These are useful to separate longer parts or tools that will not fit from front to back in the drawer.

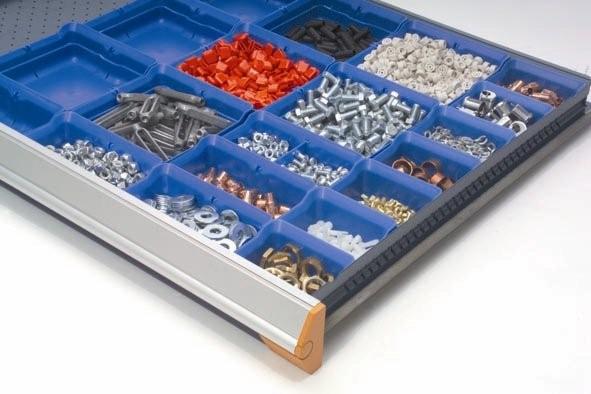

Bin Cup System

Bin Cups are removable plastic bins that are used to store smaller parts and hardware items. Bin Cups come in 4 sizes and 2 heights. The bin sizes are designed for exact fit in all Rousseau drawer widths. The 2” height will fit in a 3” Face drawer and the 3” height fits in a 4” Face drawer. The bin cups have rounded inside corners for easy part retrieval, are easily removed from the drawer and can hang on any standard bin rail system. Bins are also available in conductive material for ESD applications.

Bin Cups are removable plastic bins that are used to store smaller parts and hardware items. Bin Cups come in 4 sizes and 2 heights. The bin sizes are designed for exact fit in all Rousseau drawer widths. The 2” height will fit in a 3” Face drawer and the 3” height fits in a 4” Face drawer. The bin cups have rounded inside corners for easy part retrieval, are easily removed from the drawer and can hang on any standard bin rail system. Bins are also available in conductive material for ESD applications.

Groove Tray System

Groove Trays are plastic trays that form channel spaces for storing longer and narrow items such as drill bits, tooling, large sockets, files, etc. The trays come in sets with 2 to 5 channels that are sized to fit our standard drawer depths. There are three usable channel widths: 1”, 1.5” and 2.5” wide. They have adjustable dividers that can snap in place anywhere along the depth of the tray with an angled back for easy to read labeling.

Groove Trays are plastic trays that form channel spaces for storing longer and narrow items such as drill bits, tooling, large sockets, files, etc. The trays come in sets with 2 to 5 channels that are sized to fit our standard drawer depths. There are three usable channel widths: 1”, 1.5” and 2.5” wide. They have adjustable dividers that can snap in place anywhere along the depth of the tray with an angled back for easy to read labeling.

Hanging File Bars are available to store standard hanging files. The file bars can be installed for hanging front to back (as shown) in drawers from 18” to 27” deep. Bars are also available for a left to right orientation for drawers from 24” to 48”wide. The drawer must be deep enough to allow for the full height of the files you are hanging. Keep in mind that some drawer sizes will fit the file folders more efficiently than other sizes.

Hanging File Bars are available to store standard hanging files. The file bars can be installed for hanging front to back (as shown) in drawers from 18” to 27” deep. Bars are also available for a left to right orientation for drawers from 24” to 48”wide. The drawer must be deep enough to allow for the full height of the files you are hanging. Keep in mind that some drawer sizes will fit the file folders more efficiently than other sizes.

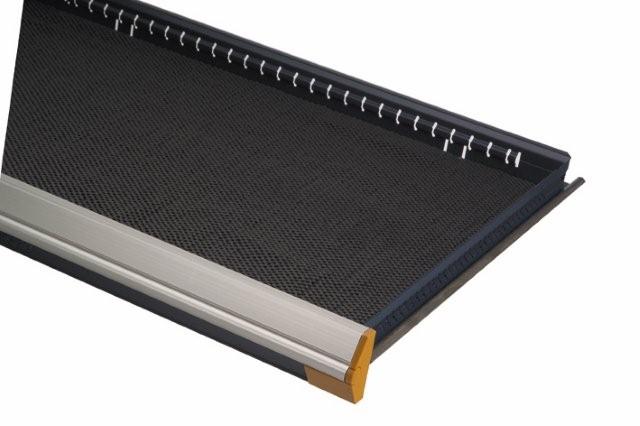

Drawer Liners & Foam Inserts

PVC Drawer Liners are a PVC coated mesh fabric that provide a protective and non-skid surface on the bottom of the drawer. This is the only protection option that can be installed under our partition and divider system.

PVC Drawer Liners are a PVC coated mesh fabric that provide a protective and non-skid surface on the bottom of the drawer. This is the only protection option that can be installed under our partition and divider system.

Foam for Protection is a ¼” thick high density foam that protects sensitive items that are set in the drawer. This option cannot be used under partitions and dividers, but can be cut to size and installed in individual partitioned compartments.

Foam for Protection is a ¼” thick high density foam that protects sensitive items that are set in the drawer. This option cannot be used under partitions and dividers, but can be cut to size and installed in individual partitioned compartments.

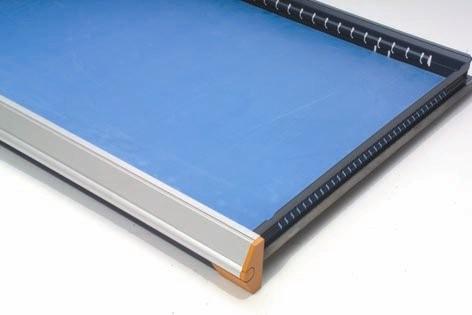

Foam for Tools is a 2-part product. The base is a ¼” high density blue foam, under a ½” thick self-adhesive black foam. The black foam is cut out to fit the shape of your specific tool set. Then the protective liner is removed and the adhesive back is pressed onto the blue base layer, providing tool slots with contrasting outlines.

Foam for Tools is a 2-part product. The base is a ¼” high density blue foam, under a ½” thick self-adhesive black foam. The black foam is cut out to fit the shape of your specific tool set. Then the protective liner is removed and the adhesive back is pressed onto the blue base layer, providing tool slots with contrasting outlines.

Foam for Collets is a 1” thick high density black foam that can be cut out or punched to fit the shape of your collets, mills, bores, or parts containers. This allows the parts or tools to stand vertically in the drawer, taking a minimum of space, while protecting them from damaging contact with each other.

Foam for Collets is a 1” thick high density black foam that can be cut out or punched to fit the shape of your collets, mills, bores, or parts containers. This allows the parts or tools to stand vertically in the drawer, taking a minimum of space, while protecting them from damaging contact with each other.

Custom Applications

Modular Drawers in Shelving insert systems are compatible with each other. So, you can mix and match within any individual drawer. You could have partitions and dividers on one side of a drawer with bin cups on the other. Or, you could have groove trays combined with foam for collets or tools. We can assist you to come up with the best insert options for your particular application for small parts or tooling.